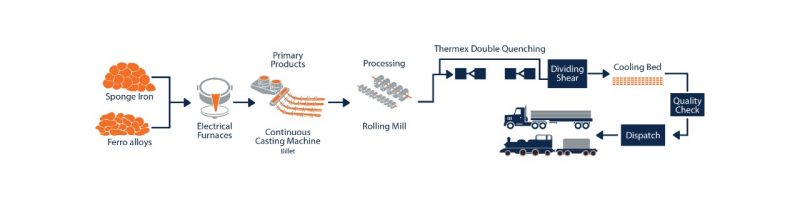

Sponge Iron __

Growth in the sponge iron production can be attributed largely to the popularity of secondary steel making route. The process of manufacturing sponge iron involves removal of oxygen from iron ore. During this process the departing oxygen causes micro pores in the ore body, turning it porous. Hence the name sponge iron. Sponge iron is an iron source with a uniform composition. It is used increasingly in Electric Arc and Induction furnaces to dilute the contaminants present in the scrap used in these processes.

Ferro Alloys __

Ferro alloys are alloys of iron with a high percentage of one or more elements. These are used in steel making, alloying of steels and in iron or steel foundries. In steel production ferro alloys are used for deoxidation of steels as well as for introduction of the alloying elements in the steel. They impart distinctive qualities to steel and cast iron.

Electrical Furnaces __

Electric Arc Furnace (EAF) is a steel making furnace, in which steel scrap is heated and melted by heat of electric arcs striking between the furnace electrodes and the metal bath. During the initial stage of primary steel making in an oxygen furnace combining oxygen with carbon in the iron eliminates carbon dioxide. For refining the composition of steel, the steel once again passes through the EAF (Electric Arc Furnace).

Continuous Casting Machine __

Continuous casting, also called strand casting, is the process whereby molten metal from EAF (Electric Arc Furnace) is solidified into a “semi-finished” billet, bloom, or slab for subsequent rolling in the finishing mills.

Rolling Mill __

Billets are first pushed to the discharging roll path by pusher and fed into roughing rolling mill (6 stands rolling mills) by rollers. The No.1 flying shear cuts the rolling piece head, and it is fed into the medium rolling mill to be rolled continuously; after the middle rolling, the No. 2 flying shear cuts the tail. After the middle rolling, the material needed for finishing rolling is produced. Finishing rolling produces qualified products for water cooling. The rolled piece is double cut through the No. 3 flying shear.

Quenching Box __

After getting released from the finished mill, the hot rolled bars enter the water spray system called the ‘Thermex System’. TRIAM A+ uses the best quality tmt bar manufacturing process – the Thermex Technology that cools down the outer core rapidly ensuring the ductility of TMT Rebars.This cooling technology is known as Quenching.

Cooling Bed __

A rolling mill cooling bed is used for the uniform air cooling of the bars and transport them in a phased manner from the entry side of the cooling bed to its discharge side. A cooling bed carefully moves and cools the hot steel rolled bars after the hot rolling process. Cooling beds are to be specifically designed considering the smallest and the maximum size of the bars being rolled for receiving, transferring, and cooling of the rolled material. In a cooling bed the temperature of the entire length of the bar is to be cooled at the same time.

Quality Check __

Rigorous testing takes place throughout the steelmaking and rolling processes to ensure that quality standards are maintained. During steelmaking, a series of samples are taken for testing at our advanced laboratories, where the latest analytical equipment and techniques are used to verify each heat’s precise chemical composition by our expert team. The test results are fed immediately back to the plant, so that sensitive adjustments can be made to correct steel composition where necessary.

Dispatch __

A final quality check is conducted in the dispatch yard before the product is shipped to customers. The company’s well-equipped laboratories also conduct mechanical tests on samples of the finished product, guaranteeing their compliance with relevant standards. TRIAM A+ FE 550D is supplied section-wise in convenient pre-packed bundles having a fixed number of pieces per bundle.